05 Mar What is CIPP? – Cured-In-Place-Pipe Lining

So you are wondering what CIPP is. CIPP stands for Cured-In-Place-Pipe Lining and has been a method of pipe repair and restoration for over 35 years in the US. This method is commonly referred to as Trenchless Technologies or Trenchless Pipe Repair and has been an approved and is the preferred method of rehabilitation for broken, cracked or damaged sewer pipes, especially for large industries. This lining is a more efficient method for pipe repair than the typical open cut methods of pipe replacement. Additionally, it is less expensive than pipe replacement and does not cause any sort of surface disruption that may require digging up sidewalks or driveways. This method can be used on virtually any variety of piping, including cast iron, clay, PVC, concrete, ABS, Orangeburg, HDPE and corrugated metal pipes. The CIPP lining process was actually established in England, and quickly becoming a popular and cost effective way to repair different pipe problems.

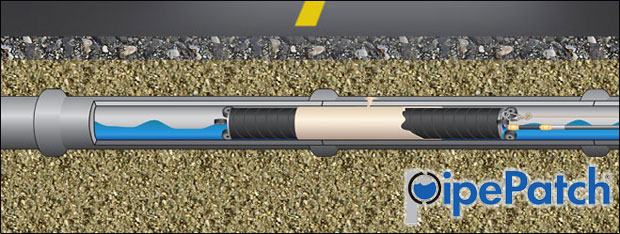

The CIPP liners are composed of layers of tubes that feature non-woven polyester felt and an exterior coating of polyurethane. The material then undergoes a process referred to as wet-out in order to add a flexible strength to the liner. When the wet-out process is completed it must be transferred to the site of installation. The CIPP liner is then positioned into the original pipe by either air or water inversion or can be winched into the proper position. Once the CIPP liner is in the proper position it is then inflated by a steady stream of air pressure or a column of water, which will actually press the lining material into the wall of the host pipe. Once the CIPP liner has become completely inflated the installers then circulate hot water or steam in order to activate the thermosetting resin material, in order for it to harden. Once the hardening has completely set, its temperature is slowly reduced, which is necessary in order to prevent the CIPP lining from shrinking (before/after video).

When the CIPP liner is properly installed the result is a “new pipe within an old pipe.” These liners are actually designed so that they are strong and stable independently and do not rely on the original pipe for any support or structural contribution. While the addition of a CIPP liner will actually reduce the overall diameter of the original pipe, this reduction is made up by the increased flow surface of the CIPP liner. This method can actually fix a number of different pipe problems. Some of the most common include root infiltration, inflow and sewer infiltration problems as well as pipes that have been offset at the joints or that feature missing pieces of pipe.

If you are experiencing pipe problems that may require CIPP technology, please contact Pipe Rehab Specialists for a quote or any additional information.

No Comments